Mission & Quality Assurance

SOLUTIONS

a.i. solutions performs continuous assessments of the engineering, technology, processes, production, and programmatic practices used to develop and operate our nations' missile defense system such that high risk attributes can be identified and addressed to increase confidence in achieving mission success while ensuring personnel safety.

Over the past 15 years, a.i. soluitons has supported the Missile Defense Agency's mission to develop, test and field an integrated, layered, missile defense system to defend the United States, its deployed forces, allies, and friends against all ranges of enemy ballistic missiles in all phases of flight.

Mission & quality assurance legacy

MDA's Technical, Engineering, Advisory & Management Support (TEAMS) Next Quality & Mission Assurance

- a.i. solutions Department of Defense prime contract

- Currently in the 4th base period of a 5-year contract

- 3rd iteration of QMA support with the MDA

MDA's Technical, Engineering, Advisory and Management Support (TEAMS)

- a.i. solutions Department of Defense prime contract

- Follow on contract to MiDAESS lasting 5 years

- The TEAMS contract was a single award

Missile Defense Agency Engineering and Support Services Contract (MiDAESS)

- a.i. solutions Department of Defense prime contract

- MiDAESS was an IDIQ contract with 3 task orders

- a.i. solutions was awarded the Quality Assurance task order and retained it for the 5-year period

Test what you fly, fly what you test

Mission and safety critical engineering that measure, verify, and validate mission success.

Quality Assurance Implementation

Did you build the right thing?

We support the implementation of quality assurance requirements by providing subject matter expertise for the identification, evaluation, and mitigation of risks associated with various aspects of the design, development, manufacturing, fielding and operation of space and missile defense systems.

Mission Assurance Implementation

Did you build the thing right?

A disciplined mission assurance process has independent assessments as a cornerstone. We support the implementation of mission assurance requirements by providing technical evaluations of designs for subcomponents, assemblies, and integrated systems associated with space and missile defense programs.

Lean more about a.i. solutions' mission & quality assurance solutions

Mission & quality assurace expertise

Mission Assurance Field Representation

When you desire direct, unfettered supplier insight, a.i. solutions creates leverage to affect value added changes and mitigate risk in a timely fasion. We support the implementation of quality and mission assurance requirements by providing on-site verification and auditing at developer facilities to ensure that robust controls are in place for quality assurance practices including foreign object debris, electrostatic discharge, and contamination.

Manufacturing, Production and Quality Assessments

a.i. solutions ensures the control of systems for operations associated with fabrication and quality by performing assessments on manufacturing, production, and quality. This includes any related measurement and analysis, which support the fabrication process, ensuring specification requirements are achieved, verified, and maintained.

Software Quality Assurance Implementation

Software Quality Assurance (SQA) reviews and assesses the adequacy of software products and processes to provide assurance that the software processes are appropriate and produce software products of suitable quality for their intended purposes.

Parts, Materials and Processes Implementation

Due to the ever-growing threat of faulty and counterfeit parts and materials, the QS Directorate further emphasizes these efforts in the Parts, Materials, and Processes Mission Assurance Plan (PMAP). The PMAP establishes the minimal requirements levied on MDA programs as a whole for the selection, approval, and overall management of Parts, Materials, and Processes (PMP) used in the design, development, fabrication, and service life of MDA products and systems. This plan documents a coordinated approach to maintain the highest quality, reliability, and availability of MDA products and systems by utilizing parts review boards at the program and MDS level. We support by (1) providing technical evaluations of Developer designs for subcomponents, assemblies, and integrated systems associated with MDA programs, (2) properly selecting Parts, Materials, and Processes to ensure MDA hardware used at all technology maturity levels can survive both natural and self-induced environments with adequate margins, (3) providing subject matter expertise for the identification, evaluation, and mitigation of risks associated with various aspects of the design, development, manufacturing, fielding and operation of MDA systems, and (4) providing subject matter expertise to promote the reliability of MDA systems.

Parts, Obsolescence

Parts Obsolescence management ensures that obsolescence is managed as an integral part of design, development, production and in-service support to minimize cost and its detrimental impact to MDA programs throughout the product life cycle.

Technical Assurance Implementation

Support the implementation of MDA quality and mission assurance requirements by (1) participating in the development and compliance verification of processes used for the design, development, test, and evaluation of mission critical hardware and software and (2) providing technical evaluations of Developer designs for subcomponents, assemblies, and integrated systems associated with MDA programs.

Audits and Audit Management Execution

The MDA/QS Verification Organization performs independent assessment & evaluation of MDA field activities, critical contractors and program offices. We focus on: a) the program’s adherence to mission assurance policies, b) the contractor’s adherence to MDA mission assurance, quality, and reliability requirements, and c) the contractor’s adherence to their own internal policies and procedures. This assessment includes an in-depth evaluation of the MDA critical product and assesses its design, quality processes, manufacturing processes, inspections and tests, with the goal of identifying risks and mitigating them. We also provide on-site verification and audit at Developer facilities to ensure that robust controls are in place for quality assurance practices including foreign object debris, electrostatic discharge, and contamination.

Ground and Flight Test Configuration Verification

We ensure Flight and Ground Testing is performed in a safe and successful manner, in accordance with Missile Defense Agency (MDA) policies and practices. QS establishes a QS Flight Test Team (FTT) and Ground Test Team (GTT) for the development and implementation of quality and mission assurance plans to support Flight and Ground Test events.

Configuration and Data Management Functions

Configuration and Data Management applies proven Department of Defense and industry standards and practices in managing configuration and technical data. Configuration management is a systems engineering process for establishing and maintaining consistency of a product’s performance, functional, and physical attributes with its requirements, design, and operational information throughout the life of the product. Data management is a system of disciplines by which data is generated or acquired to accomplish contractual development, operation and support tasks as required by the contract.

Materials Corrosion Control

Materials Corrosion Control is the prevention of deterioration by mitigating the chemical reactions that cause corrosion by using design and manufacturing practices that address selection of materials, coating and surface treatments, production processes, system geometry, and by repairs, overhaul, spare parts requirements, and preventive and scheduled maintenance.

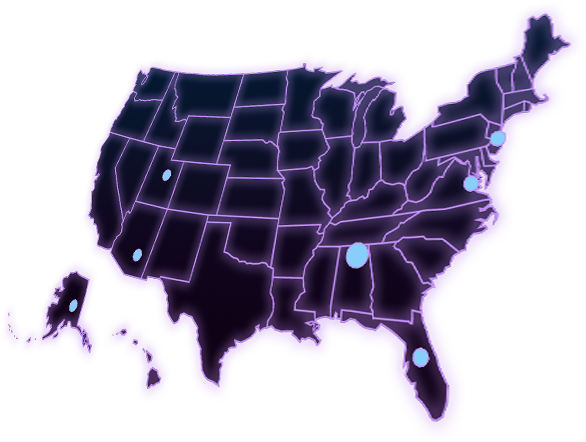

Current support locations

The majority of a.i. solutions quality and mission assurance support is provided in Huntsville, AL. However, we also provide support at a variety of customer locations including Alaska, Arizona, Florida, New Jersey, Utah, and Virgina.